Description

In the production industry, the higher the efficiency, the better. This also applies to our usually more expensive moulds. EAS Change Systems with Lift Hold and Separate are the ideal partner for customers looking for quick mould changes as well as a complete and extensive mould maintenance programme. We continue to expand the equipment production line, and currently have a variety of lifting rods, mould changing vehicles, testing devices, preheating machines and mould splitting machines. Parting machines have recently received two major orders from major manufacturing companies.

Walk-Behind Transporter solution

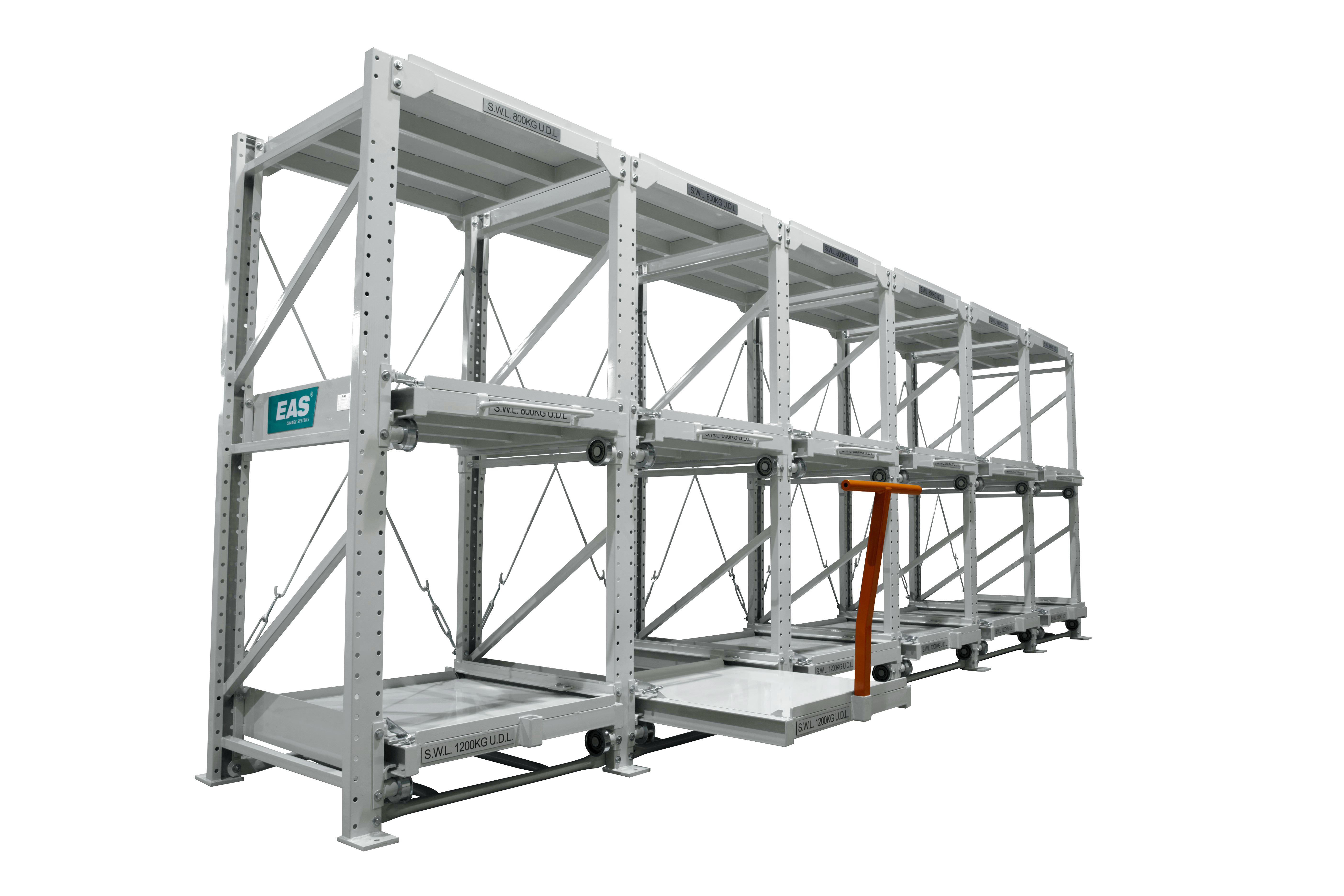

The Pull-Out Racking is designed for the safe storage and handling of tooling. The bottom and middle shelves pull out, allowing direct overhead access to stored items. Being of a modular design, the equipment can be added to, extended/adjusted to suit future change

Storage Rack solution features

Our storage racks all glide-out shelves are equipped with a unique locking mechanism which is easily handled by one person for operational safety. These shelves are supplied with front

safety lips or edges, and are fully adjustable on vertical pitch. The upright base plate is having the largest area size for this type of product, ensuring the spread of load over finished floor level and greater rack loads being obtained.. The levelling plates will be supplied to ensure rack is levelled correctly for operational use (up to max. height of 5mm)

Other Solutions

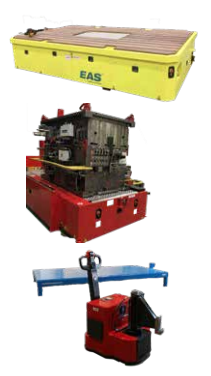

EPT/EFM

Our EFM solutions are flexible, easy to use and precise. EAS Mover series has their own special advantages. The Flexible Mover consists of an efficient and innovative system, customised to match all the

expectations of your project.

Die Change Car

Die transfer methods vary based on the size of the dies, from manual to fully automated. Dies are positioned quickly and precisely with our mould transfer systems. Mobile die change carts provide even more flexibility.

Pedestrian Tug Unit

Using a Pedestrian Tug Unit dies are brought from the storage or maintenance area to the press and returned. Several carriers can be hooked up to this car, or you can use it as an integrated unit in a tool

transporter.