Description

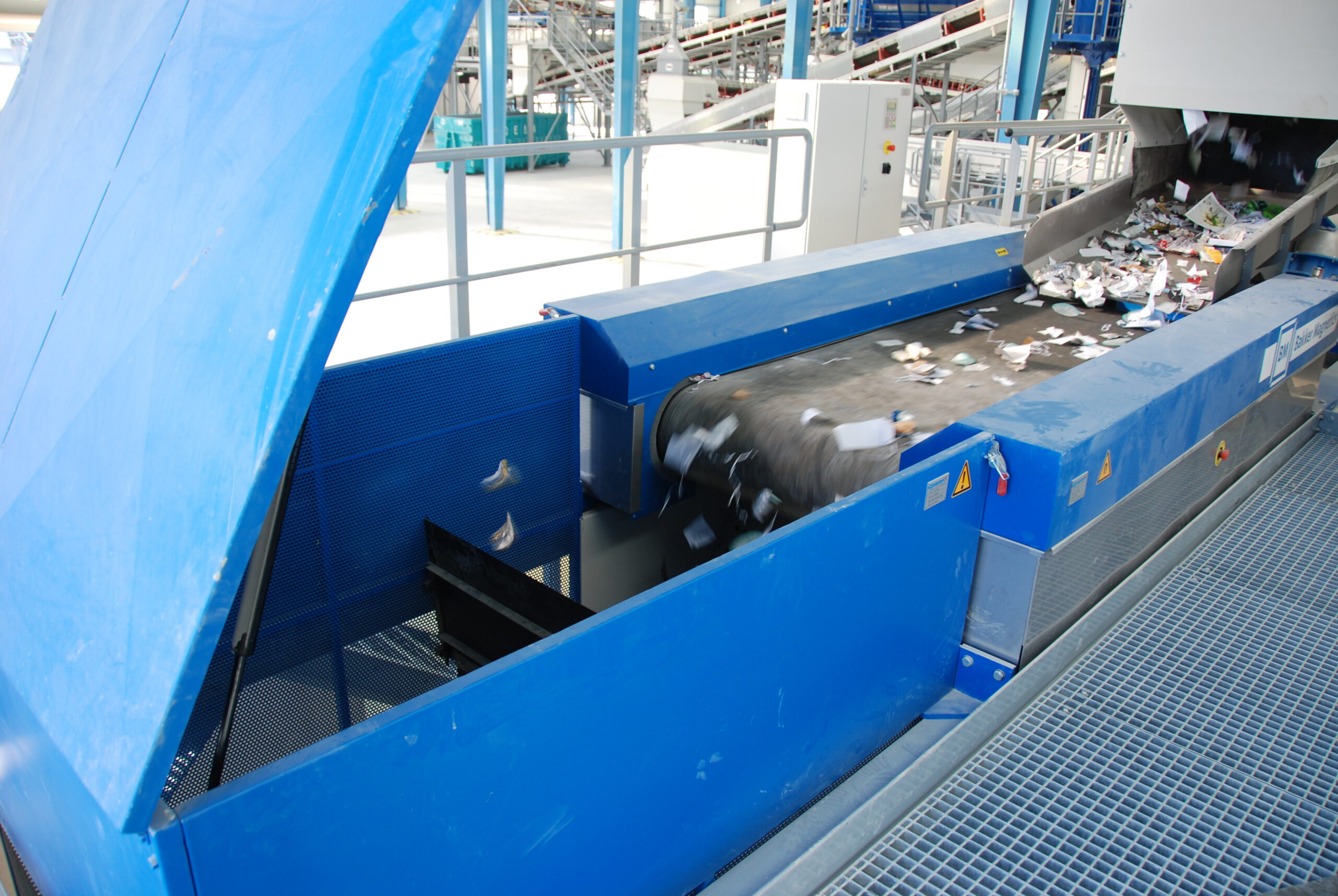

The Bakker Magnetics eddy current system offers the highest technology in non-ferrous metal separation.

Bakker Magnetics’ Eccentric Eddy Current separators has a ecentric high speed magnetic rotor and is suitable for placement in product lines where there is still a chance of iron in the product flow.

Due to its eccentric design it has a self cleaning mechanism, this means iron pollution is no longer a problem which results in a longer lifespan of the rotor. Available with our best rotor ever the 52 poles X-s rotor for superior separation results in even the smallest fractions.

The technical design of our eccentric machine is similar to the centric version and uses the same “A” class components. The modular design makes it possible to easily integrate a vibrating feeder and or an additional drum magnet. The highest number of magnetic poles available in the market combined with our best in class magnetic technology will get the most out of your residual materials!