Description

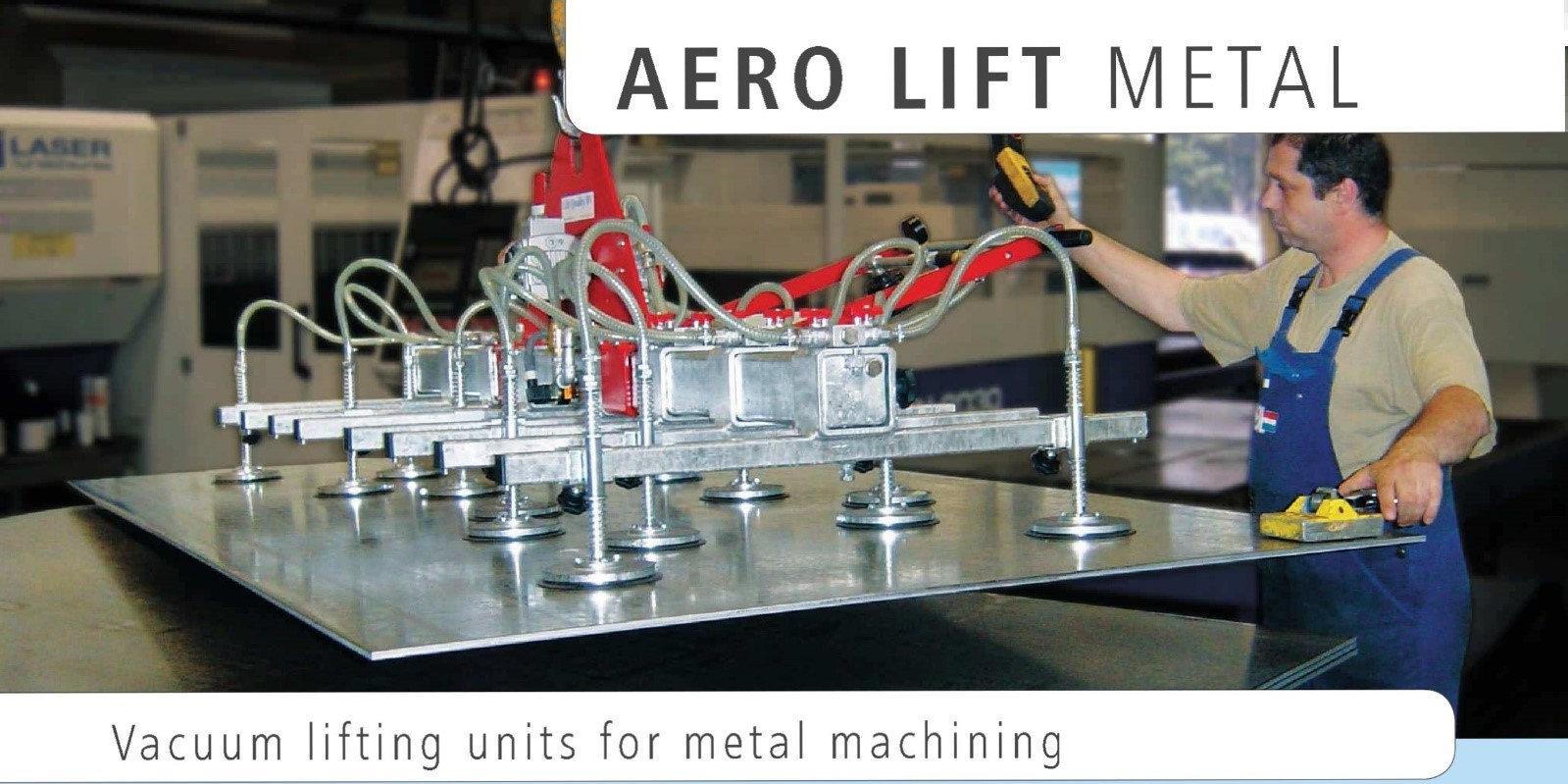

Vacuum Lifting for Sheet Metal:

Although movement of sheet material in the metal machining industry is a normal operation, it is also extremely complicated in the majority of cases.

Several employees have therefore frequently been required for loading a cutting or punching machines, ensuring that sheet material is transported quickly and with precision to the machining location. Large, extremely thin sheets in particular have proved particularly difficult to handle, due to their low intrinsic stability.

However, sheet material is ideal for handling with vacuum lifting units, thanks to its uniform dimensions and smooth, non-slip surfaces.

Even large sheets can be conveyed over long distances with these units, an example being transportation from moving floor shelving t0 a laser cutting machine.

Use of the vacuum lifting unit means that sheets can be removed quickly and precisely by a single person and then conveyed to the respective machine for further machining.

This accelerates the transportation process considerably, enhancing the efficiency of the complete workflow as a consequence.

Work is greatly facilitated by the simplicity with which the vacuum lifting unit can be operated (with an adjustable angled handle where required). Warping or even bending of the material transported is avoided through a configuration of the suction plates which suits the dimensions involved

Vacuum Lifting for Heavy Lifting

Up to 40,000 kg and more…….

Sheet material of enormous dimensions and weight is utilised in shipbuilding and the construction of pipelines or wind power generator towers. Handling of these gigantic masses will not only require a lot of workers, but also the employing of cumbersome and strenuous methods.

AERO-LIFT specialises in heavy weight applications and has proven that even weights of 40 tonnes and more pose no obstacle to the use of vacuum lifting technology.

One employee is generally sufficient for the precise and rapid transportation of surfaces exceeding 70 m² (eg for conveying to a processing machine)

Suctioning of the load in no way impairs the material and even prevents scratching of the surface. Slings and clamps can also be dispensed with.

Safety is particularly important where heavy loads are involved. The reliable traversing system, intelligent suction plate configuration and individual components distinguished by superior quality ensure that maximum stability is achieved and prevents deformation of the material being transported.

Visual and acoustic warning equipment informs the operator of problems should any occur. A vacuum tank in the hot-dip galvanised main transverse hold the material safely over a long period of time (eg during a power failure) thus ensuring that the transported load can be deposited safely in an emergency.

Use of vacuum lifting technology means that, even where heavy loads are involved, handling processes can be improved significantly. Stress on both personnel and material is relieved, processes accelerated and material flow efficiency enhanced considerably as a result

Low-maintenance pumps, a cost-effective wear part system and efficient utilisation options mean that AERO-LIFT units are especially suitable for economic and, in particular, ecological production of systems for the recovery of regenerative energy.

Pivoting up to 90°

Horizontal transportation is often inadequate when it comes to sheet material. A pivoting range of 90° is required for loading a vertical saw or removing standing boards from a warehouse or stores

Easy pivoting of even larger and/or heavy loads by a single employee can be realised without difficulty using vacuum lifting units from AERO-LIFT

Turning up to 180°

Vacuum lifters with a turning range of 180° are available which can be used to enable painting of both sides of boards. The load can be pivoted continuously (manually under electric power) and thus comfortably transported in a single action and painted on front and rear.