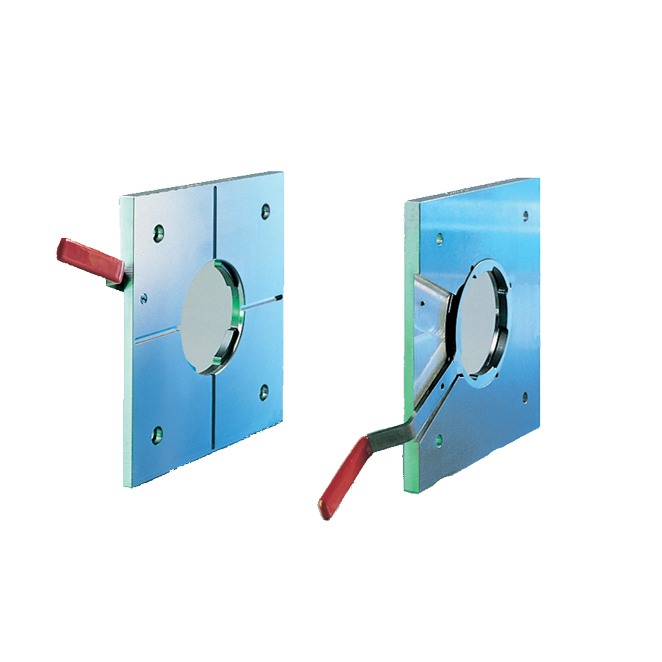

Description

Mechanical clamping systems are simple and low cost. The first step towards quicker tool change.

MECHANICAL CLAMPING SYSTEM

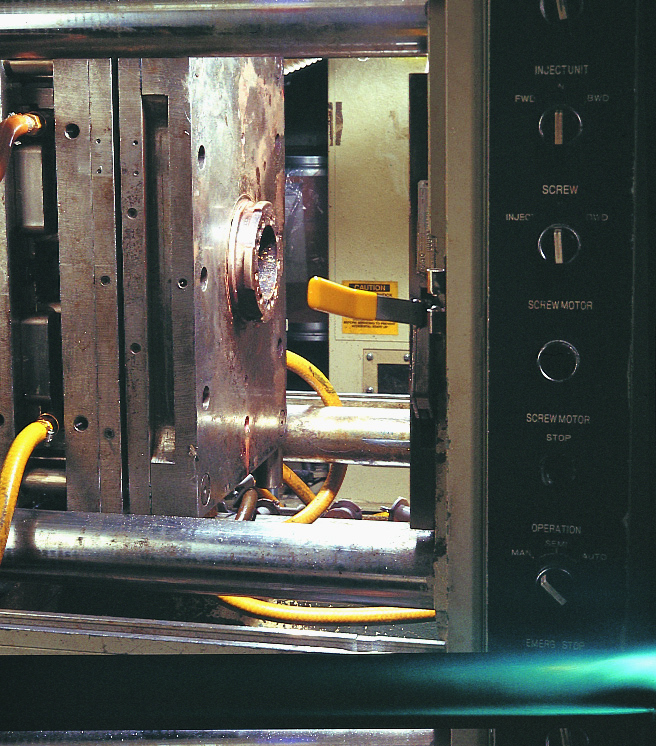

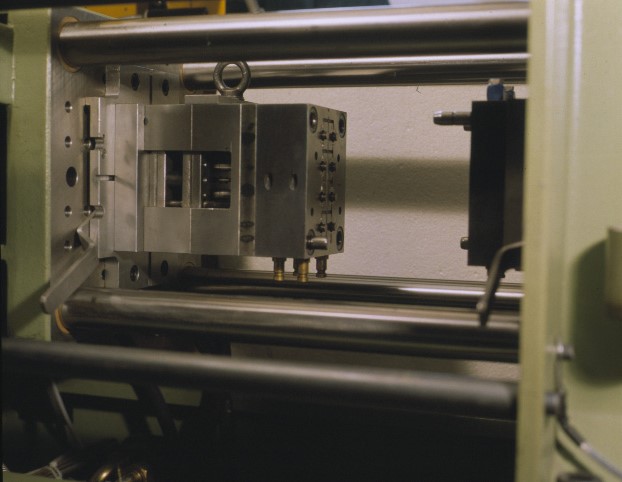

For mechanical clamping, EAS offers a manual bayonet clamping system is used on injection molding machines up to 200 T. Since there is no need to invest in hydraulic or electrical connections, this is a simple first step towards QMC automation for smaller machines.

The mould is held in position by a manual bayonet locking mechanism, easy to install and operate.

MECHANICAL CLAMPING:

simple and economic QMC solution

for small injection molding machines

no hydraulic or electric connections required

simple retrofit

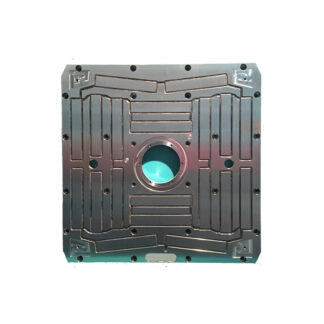

thin plates ensure minimal loss of daylight opening in the machine

available for machines with Euromap standards as well as for SPI standards

for molds with a maximum weight of 2 T

Functioning

The bayonet system locks the mold onto the machine by just turning the handle manually and stays securely locked during operation.

Installation

The centering rings on molds need to be replaced on both side of the molds by a bayonet centering adaptor.

Application

The mechanical clamping system can be installed on new and existing injection molding machines up to 200 T, using the existing mounting hole patterns.

To reduce your production costs, QMC solutions can be applied in a series of cost-effective steps. Take a look at the other solutions EAS has to offer, helping you speed up your changeover time.

Reviews

There are no reviews yet.