Description

Applications

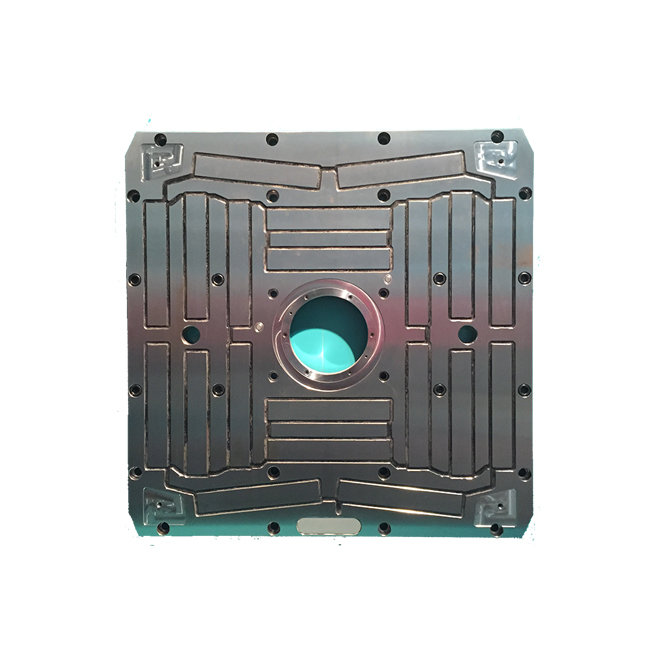

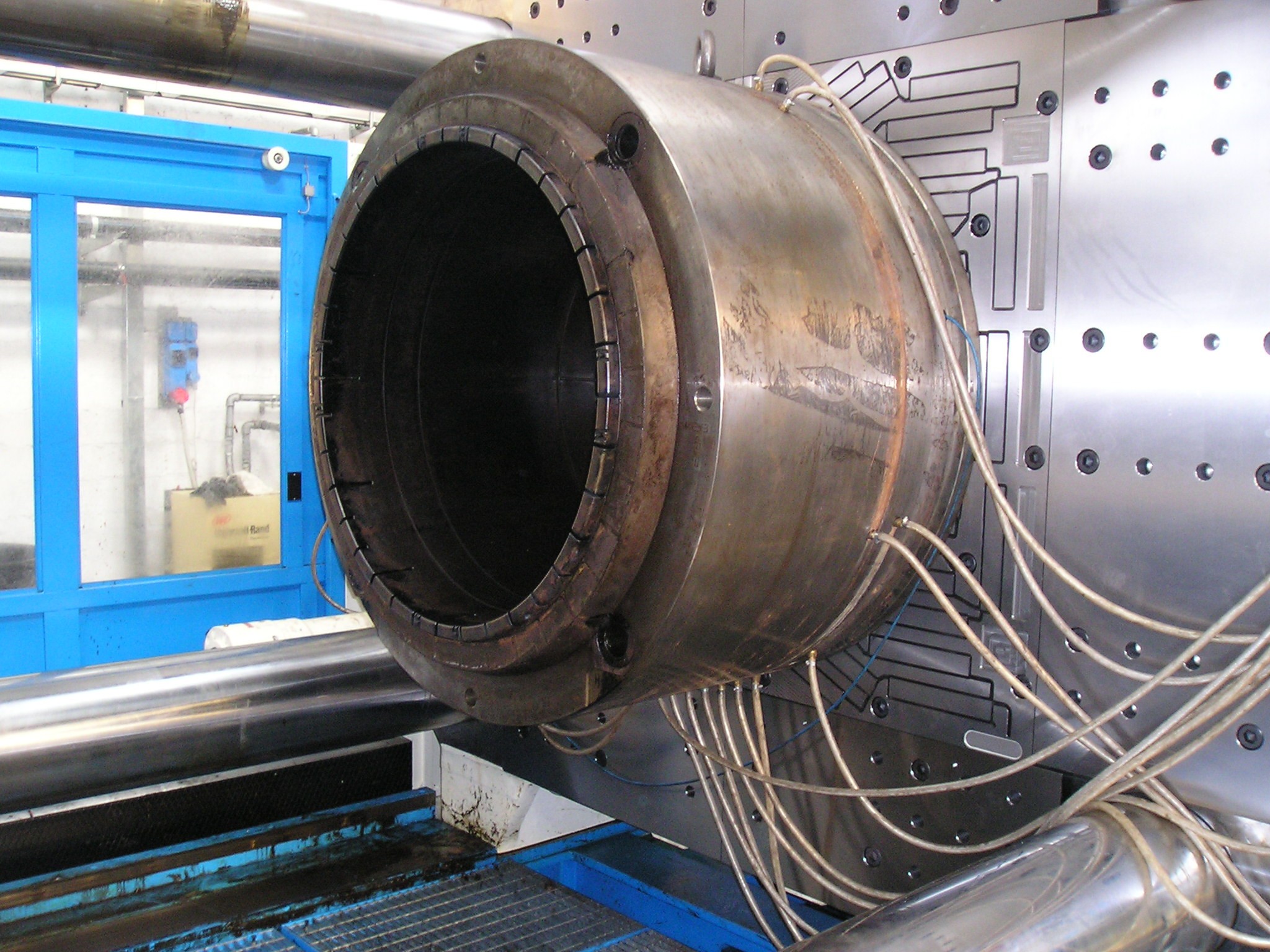

The Pressmag HP system is a compensated system. This means that each pole is not,as the Pressmag SP system,a north or as outhpole,but here the long poles are acting like the north plus pole while the frameplate acts as the south minuspole. The permanent Neodynium and AlNiCo are always active. To magnetize, the electric current

To magnetize, the electric current in the coils reverses the polarity of the ALNiCo magnets. The magnetic fields generated by the magnets are oriented to the polar face of the chuck, which becomes active and the mould is clamped. A new electric current reverses the polarity of the AlNiCO magnets and turns off the system, the demagphase and the mould is released. By concentrating all long poles for larger machines withinthe tiebar area, by adding at the sidenon magnetic fillingplates and at the back corner of these filling plates astainless steel strip for a higher magnetic flux concentration, we achieve higher force within the tiebar area.

Reviews

There are no reviews yet.